CSV could be highly-priced and time-consuming, especially when you’re validating on paper and haven’t adopted a danger-based mostly strategy to find out the right amount of testing and documentation necessary to satisfy regulatory anticipations. The FDA's Typical Principle of Computer software Validation Steering outlines these anticipations.

The purpose is making sure that a process that contributes to one high-quality product or service might be repeated constantly at exactly the same amount. Absolutely sure, you could be able to create a higher-high quality concluded merchandise under one particular set of situation, but what if you might want to make alterations in some unspecified time in the future?

A variety of types of validation are required throughout the drug products growth and production lifecycle. With this article, we are going to investigate The true secret types of validation from the pharmaceutical industry.

Process validation and verification are essential measures in almost any process improvement task. They make sure the process satisfies the look technical specs, performs regularly, and delivers the desired results. But how do you document and report the results and outcomes of those pursuits?

View the statistical Regulate charts and process capability index in authentic time so that you can act immediately.

Documentation is a vital ingredient during the good results of process validation. SafetyCulture (previously iAuditor) is an information assortment and analysis Instrument meant to ensure it is much easier for validation teams to doc process-linked information, execute the validation protocol, and continue to keep all records current.

Process validation is a systematic method to make sure that a manufacturing process consistently provides a product of predetermined top quality. Within this comprehensive guideline, We are going to investigate the significance of process validation, the key steps included, regulatory needs, as well as helpful implementation approaches as well as the potential troubles which could arise.

By validating the producing process, click here firms can minimize the risk of defects, faults, and deviations that would influence products good quality, safety, and efficacy. check here This don't just makes certain client satisfaction and also will help retain regulatory compliance and prevent highly-priced remembers.

4. Revalidation: This will likely be carried out on clinical devices. It's important when prospective validation has actually been carried out, and the final results suggest excellent may well must be maintained persistently.

six Review and revise your report The ultimate part of your report should critique and revise your report before distributing or presenting it. How did you Look at and edit your report for clarity, accuracy, completeness, consistency, and coherence? How did you structure and structure your report In keeping with the requirements and expectations within your audience and intent?

Cultivate a tradition of excellence with our electronic methods that boost performance, agility, and continuous enhancement across all functions.

Good quality groups will have to know which attributes to watch to ensure the production process runs easily. Which is why numerous organizations turn to details analytics to pinpoint the parameters that impact generation the most.

Lekan Olanrewaju is often a written content writer at MaintainX with many years of expertise in media and articles development. He has held positions at several media corporations, dealing with and leading groups at print Journals, electronic publications, and tv productions.

Specified the pharmaceutical industry’s large-chance mother nature, it can be no shock a large number of companies are careful about digitalization. Pharma manufacturers usually consider their time adopting new methods, specifically in creation processes.

Scott Baio Then & Now!

Scott Baio Then & Now! Taran Noah Smith Then & Now!

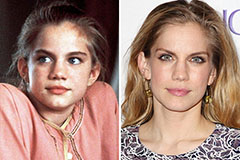

Taran Noah Smith Then & Now! Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Hailie Jade Scott Mathers Then & Now!

Hailie Jade Scott Mathers Then & Now! Suri Cruise Then & Now!

Suri Cruise Then & Now!